VR training in the oil and gas industry can go a long way in improving employee safety and ensuring preparedness. Here’s why: Hazardous chemicals, flammable gases, adverse weather conditions, heavy equipment, and dizzying heights – workers on oil rigs and gas plants face all these safety hazards, and more. It holds the unfortunate record of contributing to 74% of all deaths in the mining industry. In fact, 489 oil and gas workers died on the job between 2013 and 2017. Workplace accidents can hamper your productivity and reputation.

By creating a workplace culture of safety through VR, you can prevent accidents and fatalities and improve productivity and employee satisfaction. How exactly can this be done? Let’s explore!

An individual is allowed to repeatedly practice certain skills in a virtual environment that is created using a computer and/or a VR headset. VR training in the oil and gas industry can help employees to perfect critical procedures they need to execute on a daily basis.

VR Solutions are preferred over other methods as employees need not practice on actual machinery and yet can get first-hand experience, and gain the skills to use live machinery safely and efficiently.

Without appropriate training and the right protective equipment, your employees may get harmed. Let’s take a detailed look at the dangers that employees in this industry are subject to.

Toxic gases, corrosive liquids, and other toxic chemicals pose huge risks to employee health and safety, causing dangerous health complications with exposure. Virtual reality safety training for oil and gas industry employees can eliminate this risk.

While it is necessary for construction and repairs, it is a hazardous activity. Intense heat, sparks, toxic fumes, and so on, make it highly risky for workers, necessitating proper training and attention to prevent injuries.

Often, there are electrical or other cables lying around on the floor or just above. Employees may trip over them and fall, especially when they are rushing to complete tasks. Similarly, there could be waste material, equipment, and other obstacles in the gangways and paths of the employees, which can injure them. But you can ensure oil and gas employee safety through VR training.

Employees often have to work in pits, tunnels, storage tanks, and well-heads. The ventilation in these confined spaces is poor, and workers run the risk of inhaling toxic gases. Only with proper VR training in oil and gas industry can they avoid deadly accidents and injuries.

Over 40,000 employees have been injured due to falls, and 30% of these occur due to heights, mostly on rigs, and some due to slippery surfaces. Though mostly non-fatal, falls can result in permanent damage or disability, easily preventable with VR simulations for oil and gas operations. When there are sudden changes in levels between floors, or when they have to step onto or down from elevated platforms, employees can slip or trip.

Not handling heavy machines and those with many moving or sharp parts can be a recipe for disaster. Proper VR training in the oil and gas industry and diligent maintenance, while adhering to safety protocols during use, can help minimize risks and injuries.

Most gases and oils are flammable; when exposed to open flames, lightning, sparks, static, or even hot surfaces or friction, they can explode or burst into flames, causing a great deal of havoc and injury.

Oil and gas fields are located far from civilization, and you need boats or helicopters to get there. It often necessitates extended stay at the location, as transportation may not be available for the return journey. On-site training can hence be very expensive; the ROI often does not justify the expense of such training. VR solutions for oil and gas facilitate this training at a lesser cost.

The machinery used in oil and gas industries is very complex. There are typically different machines used to drill, pump, load, and hoist on an oil rig. If you want to install such equipment on a training site, you need to be prepared to spend millions of dollars, which is not feasible for businesses.

In addition, technological innovation has been so rapid that even existing employees need to upgrade their knowledge and skills to keep up with the new machinery. Enhancing oil and gas efficiency with VR training is the best solution to this challenge.

Oil and gas operations carry a lot of risk, and even experienced employees can get injured. Further, novice employees may also damage expensive equipment due to lack of experience. Inclement weather will only add to the woes of the trainees, and you increase the possibilities of accidents and injuries. You can mitigate these risks with virtual reality in oil and gas industry training.

There is no substitute for on-site training, as you may well be aware; theory in the classroom can only get you so far. If you want employees to be able to swiftly respond to emergencies, think critically, and set priorities, you need immersive VR solutions for oil and gas training. It is in practical situations that trainees make use of all their senses, visually identifying damages, and evaluating the threat posed by them.

Recognizing changes in the sound produced by the equipment, using muscle memory in manual operations, and so on, cannot happen in the classroom; you need to provide practical training.

The best way to evaluate how well a trainee has learnt the requisite skills is by putting them in a real-world scenario. You simply cannot determine this through a written or oral test. Certifications are critical in the oil and gas industry; ergo, it is essential to verify the training quality provided. Assessing and certifying them on live rigs or plants is expensive and risky, but much simpler with innovative VR training solutions for oil and gas.

Let’s say that you have multiple sites and your employees are spread over a large geographical area — say a few different countries. How will you ensure that you train every employee equally well, and that they acquire the necessary skills? Getting your employees from various locations to your training site will be a logistical nightmare, not to mention the high cost involved.

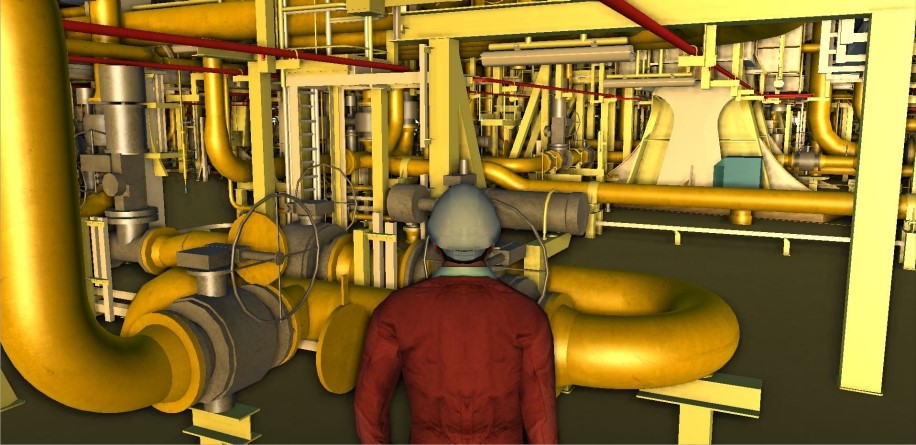

Travel for every employee, accommodation, trainers’ fees, equipment, and so on, is sure to make a huge dent in your company’s finances. However, if you choose VR training in the oil and gas industry, you can ensure high-quality training, lower cost, and zero risk. You only need to use a digital twin and recreate your actual work environment — oil rigs, storage tanks, pits, or drilling platforms.

Your employees can interact with the 3D versions of your equipment in the virtual environment, regardless of where they are — all you need to provide is VR headsets. You can save a substantial amount of money, and ensure safety for man and machine.

Often, even existing and experienced employees need training as new technology and tools are added to your repertoire. Some of the experienced and skilled staff could be nearing retirement, making it a pressing issue to train new staff and upgrade the existing employees. VR training in oil and gas industry can play an important role in helping the workforce acquire these skills.

You can partner with a VR development company to develop tailor made solutions that help the older employees train the workforce on specific scenarios and gain essential skills.

With the rate of accidents and fatalities being so high, health and safety is a priority for employers in the oil and gas sector. Adverse incidents can have a cascading effect on employee wellbeing, impacting productivity, competitiveness, attracting fines and litigation, and facing loss of reputation.

By implementing VR training in oil and gas industry, you can prepare your workforce to not only handle a wide range of hazardous materials, but to minimize them. The right training will help boost confidence and satisfaction, enhancing their wellbeing. You can also be sure of staying in compliance with domestic and international regulations and industry best practices.

When you have a solution for VR training in oil and gas industry, it can replicate the physical environment sans the physical risks and hazards. The employees can master equipment operation and other skills, and learn to respond appropriately to hazardous situations. With VR, these simulations and their variations can be repeated as many times as may be necessary without risk to trainees.

VR training in oil and gas industry is immersive and more effective, helping employees to learn quickly. When multiple senses are stimulated, the trainees learn by actually performing tasks that they will need to do in the physical world. Through such training, your employees will be able to retain the knowledge gained for a longer time, too.

Every mistake made by a trainee, and its consequences, can be instantly seen; this imprints the same in the trainee’s mind. The immediate feedback helps them to quickly correct their action, as the experience is fresh in the mind.

Though we have stressed on hands-on training, theoretical knowledge cannot be completely ignored. It is especially important where you have complex machinery and intricate processes. With VR training in oil and gas industry, relevant information can be displayed in the session – like voltage, capacity, power, purpose etc. of various equipment.

This can be displayed as text or narrated in a way that the trainee is not distracted, yet delivers the necessary information.

A purely classroom learning session has the potential to be boring and less engaging. This means that the student is unlikely to learn properly. However, if you introduce VR training in oil and gas industry, the immersive method will definitely catch the trainees’ attention and keep them engaged. Simply by wearing the VR headset, the employees can step into a whole new world.

The employee goes through a real-life scenario, and the instructions, tips, and guidelines get embedded in their mind. No classroom session with a lecture and board can match the effectiveness of VR training. Workers who receive such training are generally more confident and productive, and make fewer errors.

With VR training in oil and gas industry, you have many more opportunities for evaluation. While you can create a number of real world scenarios with VR, you can also get a significant amount of analytical data that helps in assessing trainee performance. In addition to decision-making capability, delay in response, precise movements, steady hands, and other variables can be evaluated too.

Depending on the data collected by the software for VR training in oil and gas industry, you can decide if the trainee can be certified or requires additional training.

When you use VR training in oil and gas industry, you can have customized scenarios as required for your company. You can also have on-demand training, in case you need employees to learn something quickly, renew their certification, or similar. VR training does not disrupt work, or require reassignment of personnel or facilities.

To physically train employees on your oil rig or platforms, you would need to get a group of people to train at the same time, rearrange work schedules or shifts, and disrupt work for some time or to some extent.

Another benefit of VR training in oil and gas industry is that you can create custom modules, or update the existing programs according to the changes in the actual operation. This means that you have a great deal of freedom in creating programs that help you meet your business goals.

Juego Studios has years of experience in crafting effective and customized VR training solutions for a number of industries, including oil and gas. Our dedicated team of experts can build an innovative solution for VR training in oil and gas industry that fits your needs, helps you enhance employee safety, boost productivity, and improve your revenues, gaining you a competitive edge. Check out our virtual reality and simulations portfolio to see for yourself.

VR training in oil and gas industry can give a fillip to your organization by making the workplace safer, and your workforce smarter. This can help you minimize adverse safety incidents, boosting employee wellbeing, increasing productivity, and eventually enhancing your revenues. Gain an edge over your competition by ensuring your staff is well-equipped to deal with any adverse situation, and become an industry leader.

The cost depends on several considerations like the number of scenarios you want to include, how many modules you want, how complex the processes you want to simulate are, and so on. Contact a Juego Studios executive for more details.

Going by various statistics sites and the FOG database, about a hundred employees die in the oil and gas industry each year, due to various workplace related accidents like falls, inhalation of toxic gases, explosions, fires, suffocation, and so on. By implementing VR training in oil and gas industry you can help your workforce to avoid such accidents.

It can typically take from a few weeks to several months, depending on your unique requirements. Here are some factors that influence the timeline:

You need VR headsets or a PC app which is capable of providing an experiential environment for learning. Both hardware systems collect performance data that helps in evaluation. Other essentials include motion controllers, tracking sensors, data collection devices, and internet connectivity.

Yes, it is indeed possible to integrate our VR training app with your existing Learning Management System (LMS) efficiently and within a short timeframe. This integration is crucial for creating a seamless learning experience that combines immersive VR training with your current educational framework.

Our team can help you with consultation, assessing your project’s needs. We offer custom development and integration, training and onboarding, ongoing technical support, performance monitoring and analytics, regular updates and enhancements, post-launch evaluation, and customization for future needs.

Yes, it is possible to do so, as the VR app collects vast amounts of data with regard to specific user engagement and overall performance related to important safety KPIs. By analysing these, you will be able to easily identify in what areas employees need additional training, and also understand how effective the training program is.